Vacuum purifying facility for organic small molecular

Purification of organic luminescent materials and its applications

This facility combines several advanced techniques to acquire highly purified materials. In cleaned high vacuum environment, by high temperature sublimation method, highly purified organic luminescent materials can be acquired from general chemical purified raw materials.

Introduction of the facility

Main feats:

- up to 10-3 Pa high vacuum environment for advanced materials purification

- man-machine intelligent control provides maximum efficiency

- purified material is transferred easily and conveniently by a rail.

- the sublimation temperature can be successively adjusted up to 600°C with high control precision

- high purification efficiency, multiple models to meet the different user demands

- the purification process for organic luminescent materials can be provided upon user option

Specifications:

- sublimation area temperature: RT to 600°C, successively adjustable

Keep-warm area temperature: RT to 600°C, successively adjustable; temperature control precision:±1°C - ultimate vacuum: 10Pa for rotary pump 10-5 Pa for molecular pump

- power supply: 4.5KW, 3-phase, 380V

- capacity of sublimation boat: 5-10g, 100-200g

- intelligent control: man-machine interface plus PLC

Advanced structure design

- large square view ports and interior lamps make it possible to clearly watch the sublimation and deposition status in sublimation area or keep-warm area

- the high ultimate vacuum insured the acquisition of advanced purified materials

- three-layered silica tube structure insured the non-contamination and maintained higher vacuum. The middle tube makes it easy for material withdraw and wash. The inner tube provides zone-sublimation function. Filter screens are set to prevent powder floating with airflow

- a rail is equipped for easy and safe transfer of the sublimation boat with raw materials

- filter screens and powder deposition cooling well are equipped to prevent contamination of the vacuum system

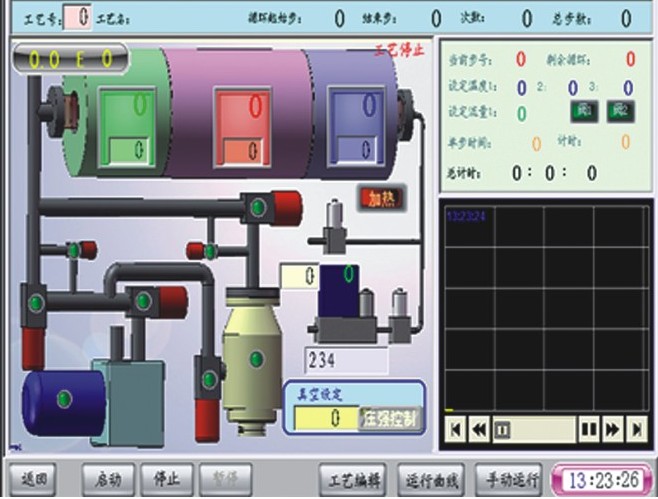

- A touch screen is used for man-machine intelligent control. The temperature variation curve and the deposition process can be set in advance, and then the facility can operate automatically. An perfect alarm system is installed.

- Mass flow meters made in Japan are adopted for its control system. The vacuum gauge can communicate with PLC, and the inlet flow rate is related to the evaporating pressure. Certain values are pneumatic controlled. Thus, the automatic control is realized.

Man-machine interface and intelligent control

Description

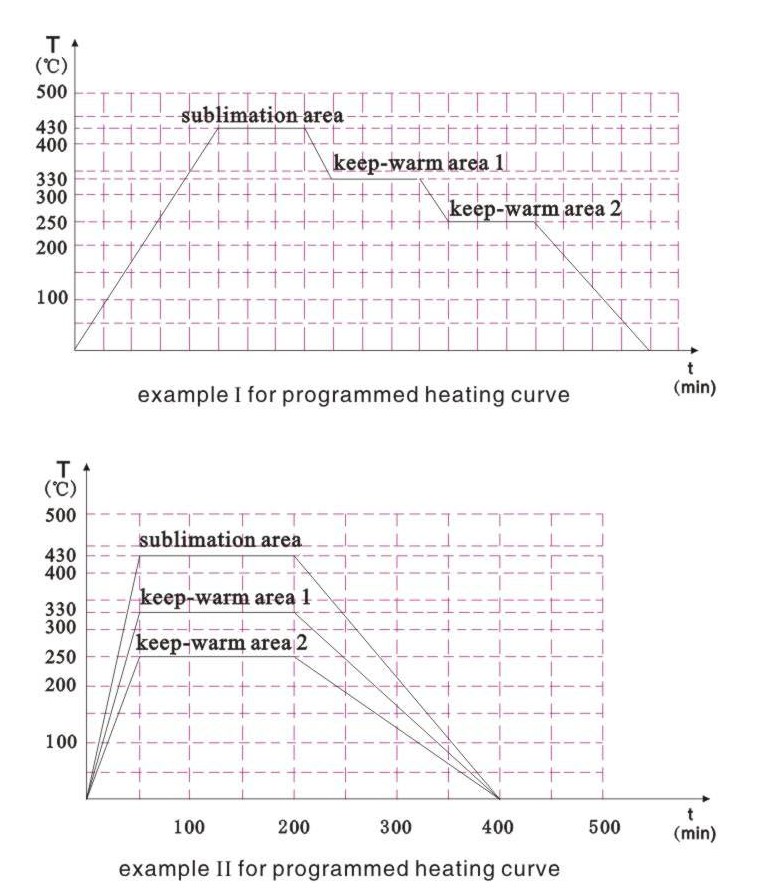

The combination of a 7”true color touch screen and PLC serve as the control center. Totally 10 processes can be programmed, each with as much as 100 steps. Internal repeatations cab be set freely. The processes can be programmed in personal computer, and upload to PLC from PC or download from PLC to PC. The seperate temperatures for three different areas the mass flowrate, the vacuum level, the operations for certain values can be programmed flexiblly in the process. Some specific functions are as following:

(1)complicated heating curves can be programmed

(2)mass flowrate can be programmed

(3)automatic evaporating pressure control

(4)automatic pumping or shutdown

(5)multifunctional failure detection and alarm

Specifications

- Power supply: 380V, 3-phase

- Output power of heating power supply: 4.5KW

- Heating temperature: RT to 600°C

- Number of programmable to processes: up to 10

- Internal repeatition circles: up to 60000

- Precision of pressure control: <1%

- Power for rotatory pump: <2KW

- Heating mode: tripple-resistance heating

- Precision of temperature control: ±1°C

- Steps for each process: up to 1000

- Operation time for each step: <60000s

- Precision of mass-flow control: <1%

Next: Production line for organic small molecular purification